Second stage leaching testwork supports targeted overall vanadium leach extraction for Bankable Feasibility Study

- Overall combined roast and leach vanadium extraction including first and second leach stages is validated at 92%, a key differentiator for AVL’s pellet roast and leach processing circuit.

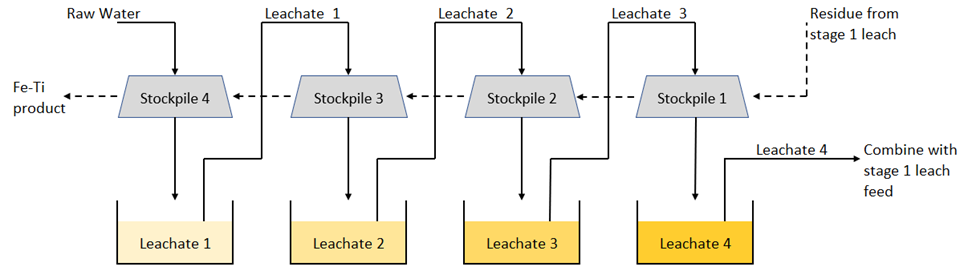

- The water-leach and wash processes impressively removed 99% of soluble vanadium from the Fe-Ti coproduct, enhancing its value for direct use in steelmaking.

- Unique AVL mechanical water leach circuit shown to be a viable, cost effective design, maximising onshore Australian extraction of high value critical mineral vanadium products.

- Work conducted at ALS testing facilities in Perth – a research partner in AVL’s Australian Government’s Cooperative Research Centre Projects scheme entitled: “Production of 99.95% Pure Vanadium Pentoxide and Vanadium Electrolytes”.

- Another successful step advancing the Company’s goal to design, build and operate the world’s next and lowest cost primary vanadium operation.

Vanadium Water Leach Meets Target for World Leading Extraction

View PDF (663KB)